Here we have a typical cylinder head that has seen better days. It’s travelled just over 180,000 km’s, and due to poor servicing and maintenance, it’s suffering from corrosion through the cooling system, and ultimately the timing belt has failed, causing damage to the valves and associated components

Please scroll down the page to see each stage involved in repairing this cylinder head back to its former glory.

A cylinder head off a 2001 Daewoo Nubira. A timing belt failure has caused extensive damage, and poor vehicle maintenance has allowed corrosion to develop.

As you can see, the valves have contacted the pistons with such force that the heads of some of the valves have broken off and caused damage to the combustion chambers and piston crowns.

All the components of the cylinder have been removed, and the cleaning process can begin.

The cylinder head and its components will spend some time (usually overnight) in our alkaline-based hot tank, which runs at 80 degrees 24/7. This process removes the bulk of the sludge and carbon deposits that can build up over the years.

The corrosion that has developed throughout the cylinder head is a major contributing factor to cylinder head gasket failure. Using quality coolant and maintaining a good earth will prevent this type of damage from occurring.

Using a Die Grinder, the cylinder head is now ready for welding to repair the corroded areas and the damage caused by the valve failure.

All the damage has been welded, and machining can now begin.

Our expert technicians have now reconstructed all the water jackets and re-shaped the combustion chambers back to original factory specifications.

The broken valves have caused damage to some of the valve seats, so they have been machined out, and new ones have been fitted.

All the welding repairs have been taken care of, and the cylinder head has been media blasted and pressure tested and is ready for machining.

Valve guides are replaced as necessary, and the head is then set up on one of our state-of-the-art seat cutting machines. All the valves and valve seats are machined to exact specifications.

The gasket face is machined to within .0001″ to provide an exceptional mating surface for the head gasket to seal.

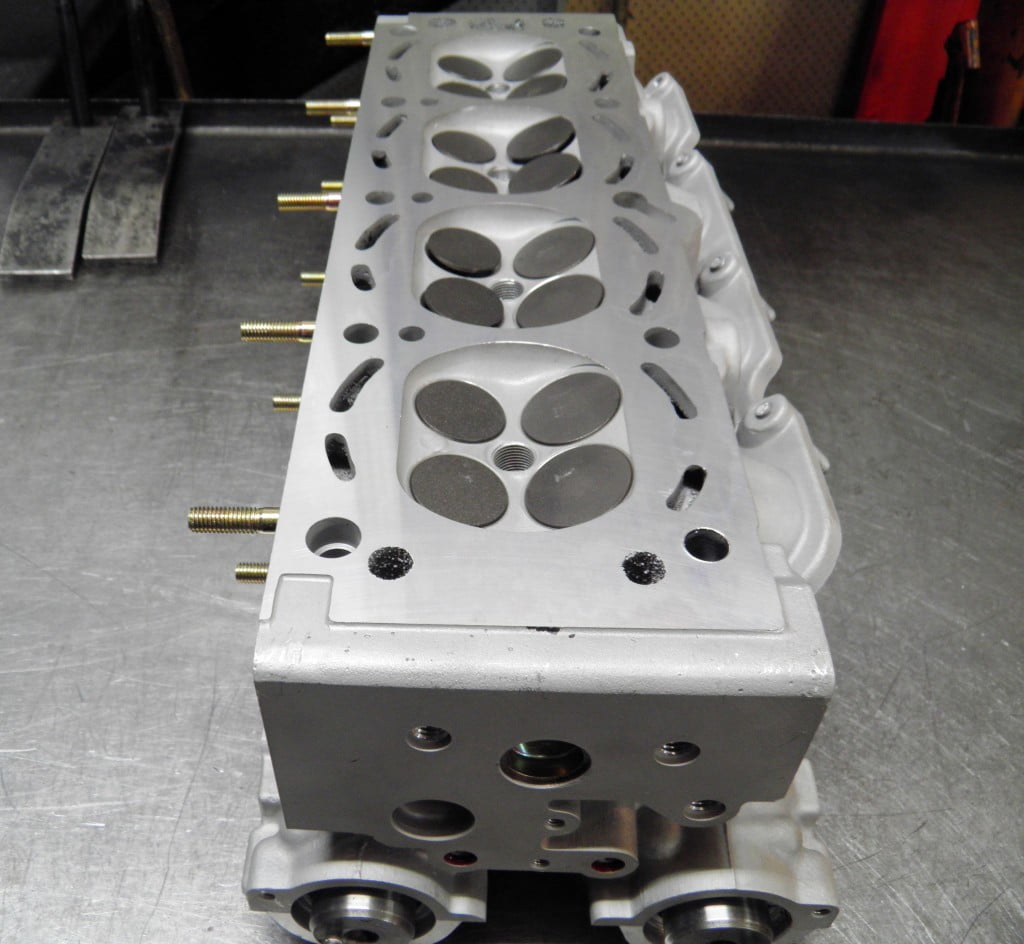

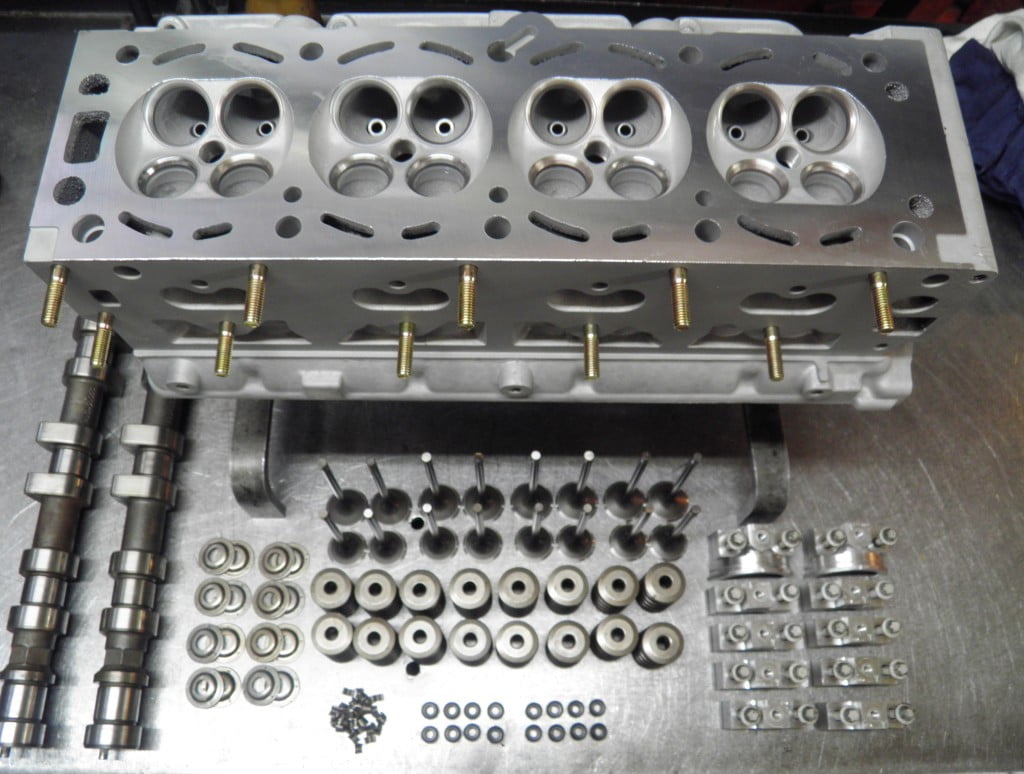

The cylinder head and components are final washed and laid out, ready for assembly.

All the components have been fitted, and the camshaft timing is set firing on cylinder one.

The cylinder head is now ready for delivery back to the customer!