Models Affected: BMW 118D, 120D, 123D, 220D, 318D, 320D, 420D, 520D, X1, X3, X5 Engines: N47D20C, N47D20A-B, N47D20D Years: 2007 - 2017 The team here at Southside Cylinder Heads have come across a...

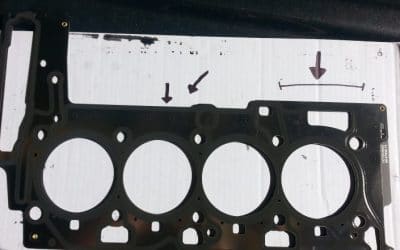

Bulletin: BMW N47 Head Gasket Differences

read more